13 Successful How To Join C Purlins Full

7 Inspiring How To Join C Purlins - Depth, flange width, edge stiffener, thicknesses and other dimensions varied between test sets. About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features

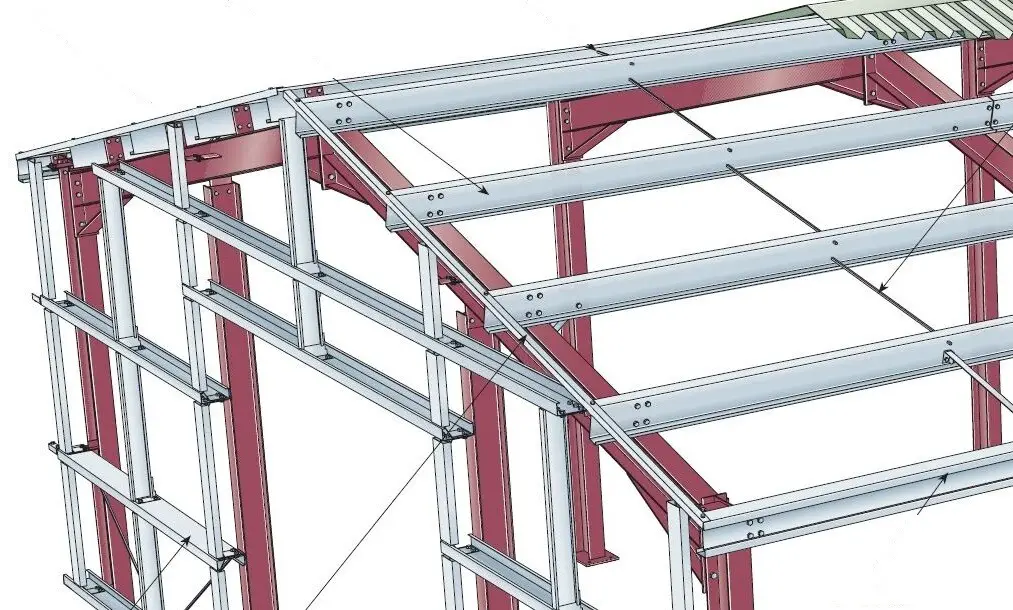

China Galvanized C Purlin Steel Profile C Channel Steel . Join narrow flange narrow flange wide flange wide flange 2 bolt cleat steel frame bolt through the outer web hole (closest to the sheeting) and the inner flange.

China Galvanized C Purlin Steel Profile C Channel Steel . Join narrow flange narrow flange wide flange wide flange 2 bolt cleat steel frame bolt through the outer web hole (closest to the sheeting) and the inner flange.

How to join c purlins

9 Value How To Join C Purlins. Fascia bolts have a shallow head that protrudes less than. I'm working on a old terrace at the back there is a single extension for kitchen bathroom i want to take out a wall that is supporting 2 purlins that have been tacked together so what i proposing to do is to strap eithier side with 6x2 timbers and bolt apply brackets over joint the length of first purlin is 4 metres and the other one is 2 metres how long will the strapping. Lap (12.5% of span) material stratco purlins are. How to join c purlins

Roof purlin are members used to directly support roof sheeting materials, and could be made of timber or steel. Available for purlin sizes 100, 150, 200, 250, 300. The size of the eave purlin may vary How to join c purlins

Purlins are supported at each end and by a series of equally spaced supporting purlins in the middle. C purlins are available in different sizes and material strengths to match the design computations of your building. This is to minimise rotation of purlins between portals and bridging. How to join c purlins

If you need a tube, use a tube rather than making one. Two types of purlins were used in the test sequences; I would get longer purlins though, they are rolled to order. How to join c purlins

Eave purlins eave purlins are usually c sections (but may be z sections or tophats in some circumstances) used to support the top of the wall cladding, where it joins the roof cladding. Bracket product codes are gpb100, gpb150, gpb200, gpb250, gpb300. Steeline c purlins are available in different sizes and material strengths to match the design specification of your building. How to join c purlins

If you need two purlins together, it is best to place them back to back. As compared with thicker hot rolled shapes, they normally offer the advantages of lightness, high strength and stiffness, easy fabrication and installations, easy packaging and transportation etc. In this video we demonstrate how to join or overlap two side wall girts (section) and connect them to a shed column (cee purlin). How to join c purlins

Once you know the run system, think about how many purlins you will need. In timber construction, purlins are nailed to the rafter or supporting trusses, while in steel roof construction, they are welded or bolted to the rafters or trusses by the means of cleats. With zeds or z section the purlin should be bolted to the lower side of the cleat with the upper flange facing up the hill. How to join c purlins

Training video from the corus bcsa training pack Any joint in the purlins that is not lapped in some fashion is going to create a pinned condition, regardless of whether it is at a support or somewhere out in the span To connect cleats, brackets, angles and other purlins together you will need some purlin bolts or if it’s fascia you need to bolt up then you will need fascia bolts. How to join c purlins

Steeline c purlins are an ideal product that provide long spans between portal frames on your commercial building. C10015 102 x 50 x 1.5mm c15015 152 x 64 x 1.5mm c15019 152 x 65 x 1.9mm c20019 203 x 76 x 1.9mm c20024 203 x 76 x 2.4mm robot building. Exact requirements will vary, but as a rough. How to join c purlins

Steeline c purlins are made from quality galvaspan® steel and are roll formed to length with. And connect them by bolting, not welding. Cold formed z (zed) and c (cee) sections are normally specified for purlins in steel structures (see their form in image below). How to join c purlins

That is the only way they are designed, you cannot join them mid span (like every structural member) without an engineer. When positioned, roof purlins should be spaced no further than 1.2 metres apart when using sheeting with a thickness of 0.7mm, and 1 metre when using 0.5mm sheeting. If it's on a farm or something , what you describe is probably ok given 4.2m is a small span. How to join c purlins

When you are installing purlins, keep in mind that they are typically placed 16 inches apart. This is going to impact how many purlins you need. Hokie66 (structural) 22 oct 15 20:13. How to join c purlins

In order for the sheets to be easily fixed to the purlins, as a rough guide they should be at least 50mm wide. When placing cee purlins into a roof the purlin should be bolted to the top side face of the cleat with the open c facing up the hill. How to join c purlins

Galvanized Purlin CEE 10†x 2.5†16GA 12’L . When placing cee purlins into a roof the purlin should be bolted to the top side face of the cleat with the open c facing up the hill.

C Purlin Manufacturer in China by Shanghai Zeli . In order for the sheets to be easily fixed to the purlins, as a rough guide they should be at least 50mm wide.

C Purlin Manufacturer in China by Shanghai Zeli . In order for the sheets to be easily fixed to the purlins, as a rough guide they should be at least 50mm wide.

China Galvanized Steel Profiled C Roof Purlins Metal . Hokie66 (structural) 22 oct 15 20:13.

China Galvanized Steel Profiled C Roof Purlins Metal . Hokie66 (structural) 22 oct 15 20:13.

Secondary Framing GMR Prefab Building . This is going to impact how many purlins you need.

Design of Roof Purlins Structville . When you are installing purlins, keep in mind that they are typically placed 16 inches apart.

Design of Roof Purlins Structville . When you are installing purlins, keep in mind that they are typically placed 16 inches apart.

China Galvanized Cold Rolled Steel C/Z Steel Purlins . If it's on a farm or something , what you describe is probably ok given 4.2m is a small span.

China Galvanized Cold Rolled Steel C/Z Steel Purlins . If it's on a farm or something , what you describe is probably ok given 4.2m is a small span.